ALLTEK Garnet sandblast media

High performance and exceptional results

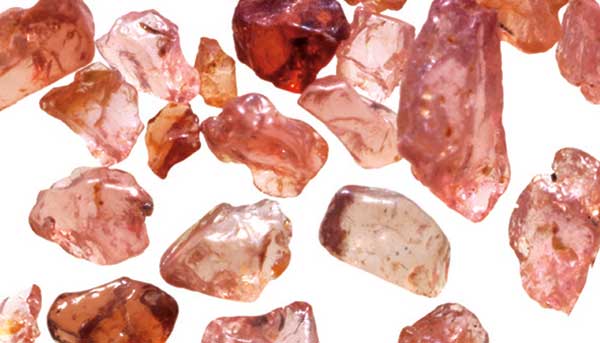

Garnet sandblast media

ALLTEK alluvial garnet blasting abrasives deliver high performance and exceptional durability — optimized by BARTON’s multi-generation garnet processing expertise. From coarse through fine, BARTON offers garnet abrasives for a wide range of sandblasting applications.

Major Industries & Applications

Delivers a superior surface finish

ALLTEK garnet grains clean deep into cavities and pitted areas down to bare metal, removing all rust, soluble salts and other contaminants to develop a surface that is virtually free of embedments, rogue peaks, and troughs. ALLTEK garnet sandblasting abrasives improve coating adhesion and coating life by producing a clean substrate with a uniform surface profile.

Can be used on a variety of substrates

ALLTEK is ideal for use on steel, aluminum and other sensitive substrates.

The ALLTEK grade required for a particular application is determined primarily by the profile specified and the thickness and type of coating/contaminant to be removed.

Low dusting offers better visibility and safety

BARTON alluvial garnet is a 100% natural, nonferrous inert mineral with less than 0.1% respirable crystalline silica and no heavy metals. It produces less dust than many other blasting abrasives, resulting in improved visibility, less disruption to adjoining work areas, and safer working conditions. ALLTEK alluvial garnet poses little or no health or environmental risks.

ALLTEK garnet is available in two, sandblast media grades

ALLTEK garnet blasting abrasives are manufactured under tight QC/QA controls and guaranteed to meet BARTON’s high and all current industry standards, including U.S. Navy MIL-A-22262B(SH), SSPC-AB 1(Type 1, Class A). Our blast media grades are QPL Listed and CARB certified.

30/60 PLUS

Intermediate

Widely used for new steel and maintenance work on coatings up to 20 mils. Typically produces a 2.5-3.5 mil profile on steel.*

80 HPA

Medium

Ideal for steel, aluminum and other sensitive substrates, this is the preferred abrasive for most vapor-blasting applications. Typically produces a 2.0-2.8 mil profile on steel.*

Standard Packaging: 55-lb. paper bags, 2,200-lb. and 4,400-lb. bulk bags.

*Profile ranges cited are typical for dry-blasting applications at usual pressures (90-100 PSI). The substrate, air pressure and other factors will impact the actual profile achieved. Select the proper grade of BARTON garnet sandblast abrasive based on test results conducted under actual field conditions.