BARTON ADIRONDACK HPX waterjet abrasive is the premier abrasive for waterjet cutting

ADIRONDACK HPX – The hardest, and sharpest garnet abrasive in the world.

Developed in cooperation with the pioneers of abrasive waterjet technology and produced to specifications tailored to the industry, ADIRONDACK HPX is the abrasive that waterjet cutting equipment is designed for.

ADIRONDACK HPX has a measured rate of breakdown and produces sharp, angular cutting edges. These sharp, angular grains cut more quickly and offer superior edge finishes. Setting the standards of BARTON’s high quality abrasives requires additional processing stages, and strict attention to detail during the refining process. As a result, this high-purity garnet abrasive costs more but also delivers superior cutting results. Our tight, consistent control of the particle size distribution maximizes the performance of your waterjet.

BARTON 80 HPX Abrasive is the most-versatile hard-rock media available for waterjet cutting.

Sharper Edges Cut Faster

Mined and milled in the USA at our New York operation, ADIRONDACK garnet has a unique crystalline structure that produces sharp, angular edges. These unusual traits enable HPX to outperform all other abrasives.

Faster Cutting Increases Productivity

Because of these sharp, more angular edges, ADIRONDACK HPX cuts faster than other waterjet media. Its one-of-a-kind crystalline structure and sharper edges mean ADIRONDACK HPX cuts through material faster; empowering the operator to do more in less time.

Better Edge Quality Improves the Cut

BARTON HPX garnet abrasives produce a better edge quality and can be used in demanding applications where other abrasives fall short.

Less Dust Reduces Operator Risk

ADIRONDACK garnet is the cleanest waterjet cutting media available.

Cleaner Operation Means Less Downtime

The superior hardness of ADIRONDACK garnet means our ADIRONDACK HPX produces less dust than any other media available. The result is a cleaner workspace, less airborne material, and less downtime due to clogged jets or erratic abrasive feed.

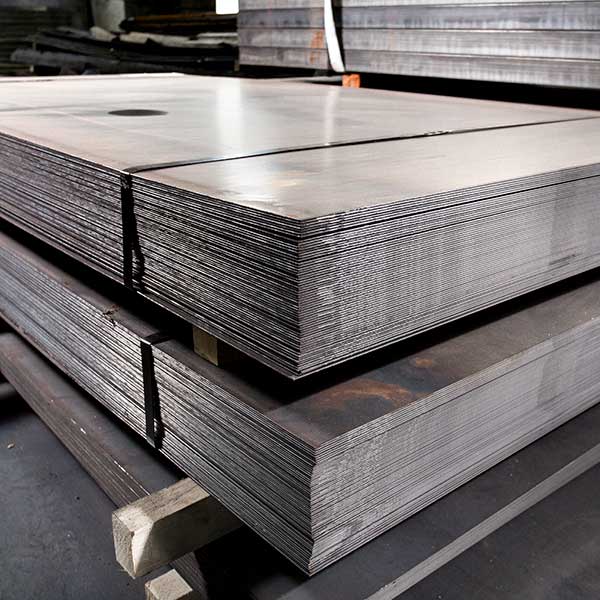

An abrasive that matches every waterjet cutting application

Whatever your industry, whether you are cutting thick, heavy metals and stone or thin, delicate materials, our ADIRONDACK HPX performs with the speed, edge quality and surface finish you need for cutting:

ADIRONDACK HPX garnet abrasive is available in 8 standard grades

50 HPX

65 HPX

80 HPX

85 HPX

120 HPX

150, 220, 230 HPX

Standard packaging for BARTON HPX includes 55-lb. paper bags, 2,200-lb. bulk bags and 4,400-lb. bulk bags.

LEARN MORE

Call 800-741-7756 or contact us for more information about high-performance HPX waterjet media.