Garnet blast media

Enhanced speed for increased productivity

Sand blast media

BARTON garnet blast media (also referred to as sand blast media) is harder, heavier and more durable than other blast abrasives. It cleans faster and significantly increases productivity while reducing abrasive consumption. Reduced abrasive consumption leads to significant savings in shipping, handling and disposal. Available in 5 different grades, BARTON’s garnet blast media offer you choice and flexibility in meeting specific application, performance and budgetary needs.

Garnet is ideally suited to recycling when used in blast-room settings, typically providing three to five turns, making it one of the most economical mineral abrasives on the market

BARTON blasting media

The harder the abrasive, the shorter the blast time

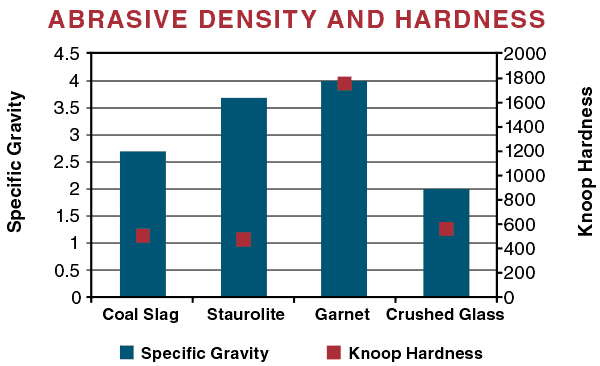

BARTON garnet blast media is 2 to 4 times harder and up to two times heavier than ordinary abrasives like crushed glass, coal slag, olivine and staurolite. Blasting with harder, more dense abrasives increases cleaning effectiveness, leaving a consistent, even profile that help ensure coating longevity. The table below compares the hardness of BARTON’s garnet to the hardness of other abrasives frequently used for surface preparation. Greater density and a higher Knoop Hardness Number are your assurance that BARTON garnet is the ideal material for high-performance abrasive blasting.

Superior surface quality

BARTON garnet blast media scour deep into cavities and pitted areas down to bare metal, thoroughly removing all rust, soluble salts and other contaminants. Our garnet abrasives are ideal for use on steel, stainless steel, aluminum and other substrates. BARTON garnet products improve coating adhesion and coating life by producing a clean substrate with a uniform surface profile virtually free of embedded particles, rogue peaks and troughs.

Low dusting, safe to use, recyclable

BARTON garnet blast media is a 100% natural, nonferrous inert mineral with <0.1% respirable crystalline silica and no heavy metals. Our garnet poses little or no health or environmental risks, and it produces less dust than many other blasting abrasives resulting in improved visibility, less disruption to adjoining work areas and safer working conditions. Our garnet abrasives blasting media meet all current industry standards and are certified by the California Air Resources Board (CARB) for permissible dry outdoor blasting.

Garnet is ideally suited to recycling when used in blast-room settings, typically providing three to five turns, making it one of the most economical mineral abrasives on the market.

Broad product line

BARTON’s garnet blast media offer you choice and flexibility for meeting specific application, performance and budgetary needs.

ADIRONDACK

ADIRONDACK The most refined hard rock garnet abrasive in the world delivers faster cleaning and impeccable surface quality

36 CG – Construction-grade cleaning power where removal speed is a priority. Used to remove thick coatings, marine fouling (20–50 mils) and rust. Typically produces a 3.5–4.5 mil profile on steel.

30/60 CG – Used to remove heavier coatings (up to 40 mils) and rust while controlling profile. Typically produces a 2.5–4.0 mil profile on steel.

ALLTEK

Globally sourced alluvial garnet processed to BARTON’s high quality standards offering excellent performance and surface quality.

30/60 PLUS – General-purpose grade used for new steel and maintenance work on coatings up to 20 mils. Typically produces a 2.5–3.5 mil profile on steel.

80 HPA® – Used on steel, aluminum and other sensitive substrates. Typically produces a 2.0–2.8 mil profile on steel.

The BARTON Group® stands behind all our products with a 100% Quality Guarantee.