ROCTEC Waterjet Nozzles/Mixing Tubes

ROCTEC abrasive waterjet (AWJ) nozzles (sometimes called mixing tubes or focusing tubes) have provided unrivaled cutting performance for over 30 years.

Made using Kennametal’s proprietary material and process technology, ROCTEC nozzles are extremely durable and resistant to abrasive and erosive wear. The manufacturing process ensures consistency in each nozzle, eliminating the need to reprogram a job when replacing a nozzle.

Users experience longer cutting periods while maintaining precision performance. Choose from three styles of ROCTEC AWJ nozzles: 100, 500 and APX.

We are just a phone call away if you need help determining which ROCTEC nozzle/mixing tube is best for your waterjet machine and cutting operation. Call 800-741-7756 or write to us using the form in the MORE INFO tab at the right.

The ROC Process

ROCTEC composite carbide is a tungsten carbide-based material made by the patented Rapid Omnidirectional Compaction (ROC) process exclusive to Kennametal.

This process enables these advanced ceramic materials to be combined without using a soft metal binder and with very short consolidation cycles – minimizing the natural tendency of ceramic particles to enlarge when exposed to high heat for long periods.

Maintaining extra-fine grain size means better nozzle performance resulting in an extremely durable material that fiercely resists abrasive and erosive wear.

Kennametal and ROCTEC are trademarks of Kennametal, Inc.

Superior Wear Resistance & Greater Accuracy

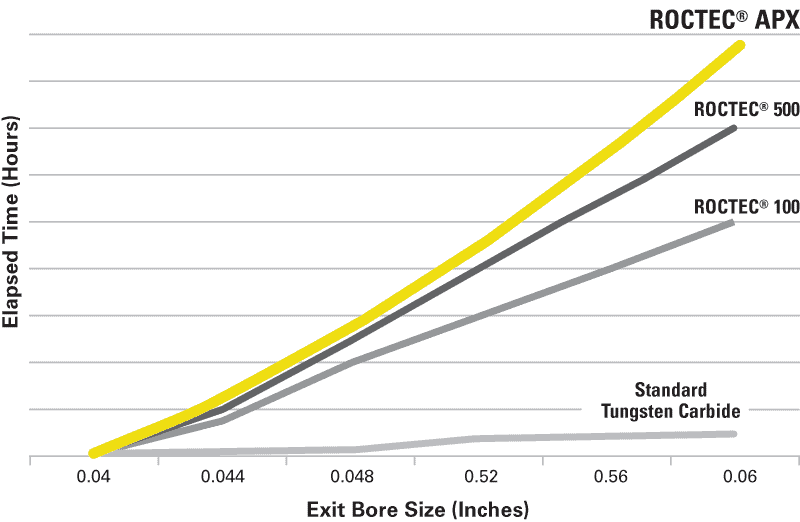

Superior wear resistance means a reduction in the number of AWJ nozzles purchased over time. Longer AWJ nozzle life also results in a better jet pattern and increased velocity. This means faster average cutting speeds and significantly less downtime for nozzle replacement and system calibration.

This also translates to greater dimensional accuracy and the ability to perform longer, uninterrupted cuts. These enhancements ensure a more cost-effective cutting process.

All leading abrasive waterjet system manufacturers design their systems with ROCTEC AWJ nozzles (also called mixing tubes or focusing tubes).

All leading abrasive waterjet system manufacturers design their systems with ROCTEC AWJ nozzles (also called mixing tubes or focusing tubes).

- Consistent and long service life

- Superior wear resistant

- High hardness Vickers 25.5-27.7 kg/mm2

- Longer service life than tungsten carbide

Comparative testing documents the extended service life provided by ROCTEC nozzles/mixing tubes versus products made from tungsten carbide/cobalt.

ROCTEC has been the industry leading technology for over 30 years. Made in the USA and distributed by BARTON International. Don’t settle for less.

BARTON stands behind all our products with a 100% Quality Guarantee.

![]()