Waterjet Cutting Stories

The Way of Water

Read the story in FF Journal about Craig Newell Welding Inc of Cambridge Springs PA and their exclusive use of Barton garnet. Craig has not had any issues with cutting head clogs, which Newell attributes to consistently using high-quality abrasive. Newell says his company now uses Barton garnet exclusively. “We’ve tried other abrasives and we keep going back to Barton. The quality is excellent. ” Read the complete article from FF Journal (PDF)

Adirondack 50HPX Does it All

Garnet sand is the lifeblood of abrasive waterjet cutting. But not all garnet is equal. That’s the opinion of Brian Yeakel, plant manager at Penn Stainless Products Inc. in Quakertown, featured in the FF Journal. The family-owned service center, founded in 1979, exclusively cuts with Adirondack 50 HPX garnet produced by Barton International in Glens Falls, New York. The right garnet ensures that the service center’s cutting meets customer demands. “We’ve been offered samples of garnet from other suppliers, but they don’t cut the way Barton’s does.” Read the complete article from FF Journal (PDF)

Full Access

In this FF Journal feature, learn more about Fenton Mobility Products, a manufacturer of seat bases that ensure wheelchair passengers’ safety in vans and other ADA-compliant vehicles. The Buffalo, NY-based company cuts A514 Grade B ½-inch plate steel to make its safety latches and turned to BARTON Adirondack for an efficient alternative to the 80-mesh alluvial garnet it had been using. Read the complete article from FF Journal (PDF)

Precision Waterjet Cutting Gains Competitive Edge

IRC Aluminum and Stainless, based in Portland, OR operates 4 large format waterjet cutting systems, cutting a variety of metals. Learn about their comprehensive abrasive testing and trials comparing BARTON Adirondack HPX® hard rock abrasive and traditional general purpose 80-mesh alluvial garnet when faced with cutting 6” titanium. A switch over to Adirondack HPX® plus the addition of Barton’s Trident cutting head yielded significant increases in cutting speed and production uptime. Read the complete article from FF Journal (PDF)

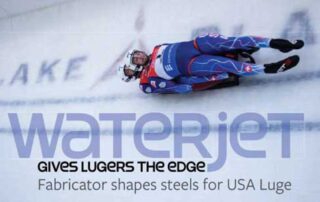

Waterjet Gives Lugers the Edge

The USA Luge team sleds are zoom through the curves, turns, and straightaways of a 1-mile track made of packed snow and ice, with speeds up to 90 MPH. One-thousandth of a second can make the difference between gold and silver. Read about how Accurate Waterjet evaluates and selects the right abrasive for this demanding job. Read the complete article from The Fabricator (PDF)

Abrasive Shortage Sent Fabricator on Frantic Search

Imagine a custom fabrication shop that cuts, forms, machines, welds and finishes hoppers and chutes using all types of metals for the dairy, food processing, wastewater and pharmaceuticals industries. Now, imagine that fab shop running out of the waterjet abrasive upon which its business depends. It nearly happened to American Metalcraft Industries (AMI), which unexpectedly had to find a new source of waterjet cutting abrasives. Read the complete article from FF Journal (PDF)

Anchors Aweigh

Read about fabrication team at Woods Hole Oceanographic Institute working on manned submersibles, tethered vehicles and autonomous, free-swimming craft that operate under Antarctic ice, in temperate Atlantic waters, or in the black waters of Challenger Dee, the deepest known point in the Earth’s hydrosphere. Their shop cuts exclusively with Adirondack 80 HPX, with 60-70 cutting jobs daily across a diverse mix of materials. Read the complete article from FF Journal (PDF)

The Difference between the Right or Wrong Abrasive

Waterjet is a clean and consistent cutting option for thick materials but if the garnet used is not high quality, abrasive clogs midstream can result in costly scrap. That is exactly what Rennline Inc, a fabricator of performance parts for European vehicles experienced when cutting 8” titanium. After testing the options, they switched to BARTON 80 mesh to gain cleanliness and uniformity of material. Read the complete article from FF Journal (PDF)

Making the Right Waterjet Abrasive Choice

The Fabricator, September 2014

Unsure of the proper abrasive to use? See MAKING THE RIGHT WATERJET ABRASIVE CHOICE, authored by Randy Rapple. Selecting the right waterjet abrasive type and size can make a significant difference in the performance and profitability of your waterjet equipment. Read the complete article from The Fabricator (PDF)