Best abrasive for waterjet cutting

Sharp, durable cutting medium

Almandine garnet is considered the mineral with the best characteristics for waterjet cutting, delivering optimal hardness, density, toughness, and particle shape for waterjet cutting. These four factors combine to determine cutting speed and nozzle wear.

Enhanced speed and edge quality

BARTON garnet abrasives are available in more than a dozen grades across our ADIRONDACK, ALLTEK, and ECOTEK product lines. Our unequalled line of high-performance abrasives gives you the ability to choose the right grade for every application.

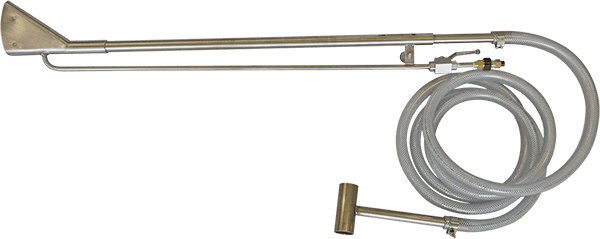

BARTON Trident Waterjet Cutting with garnet abrasive

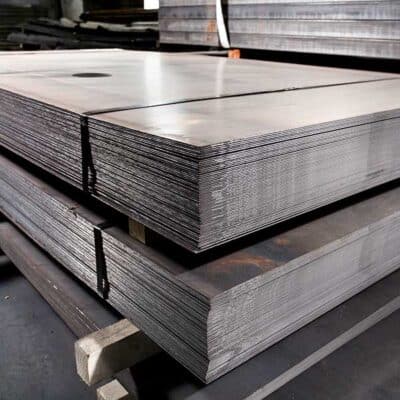

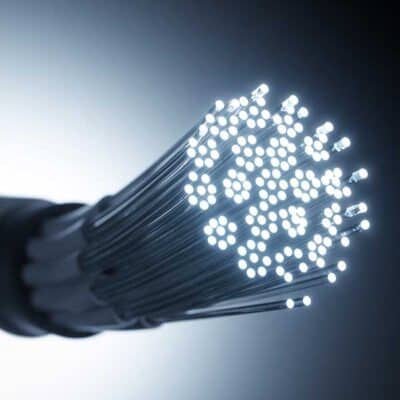

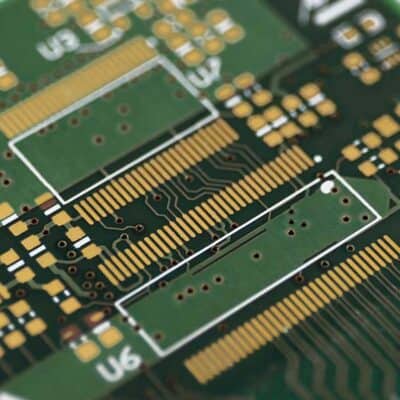

Whatever your industry, whether you are cutting thick, heavy metals and stone, or thin, delicate materials, there is a BARTON waterjet abrasive that performs with the speed, edge quality, and surface finish you need for cutting:

● Steel ● Titanium ● Stone ● Aluminum ● Composites ● Ceramics ● Glass ● Laminates ● Brittle materials ● Fiber-optic cables ● Printed circuit boards ● Precious metals

Optimal hardness

Fabricators need to find the right balance between cutting speed and component wear. A hard abrasive cuts faster but can erode the nozzle too quickly. A soft abrasive extends nozzle life but slows down cutting speed. BARTON garnet falls between 7 and 8 on the Mohs scale, which offers a good balance between cutting speed and nozzle life.

Ideal particle density

The principal cutting force of a waterjet is a function of mass multiplied by velocity. The ideal abrasive has the heaviest particle that the water stream can accelerate to maximum velocity. A waterjet abrasive with low density may be too light to pack much of a punch. One that is too dense, or heavy, can’t accelerate to the velocity needed to do the job. BARTON almandine garnet hits the sweet spot. It has a density of 4.0 (four times the weight of water) and is in the ideal range for both punch and acceleration.

Balanced toughness and efficiency

When an abrasive is “too tough” and “low friability,” its edges tend to round off during the mixing process, making it too dull to cut well. But particles that are too friable break down in the focusing tube and end up being too fine to cut effectively. BARTON almandine garnet abrasives have a semi-friable nature. They break apart into smaller pieces with sharp, angular cutting edges that cut with greater efficiency.

Best particle shape

The most suitable particle shape for a waterjet cutting depends on the material being cut and the edge-finish requirements. Sub-angular grains, like our ADIRONDACK HPX garnet abrasives, cut more quickly and offer superior edge finishes. Sub-rounded grains, like those found in ALLTEK HPA alluvial garnet, are used in more general-purpose cutting.

Purity, size consistency and cleanliness

BARTON garnet is processed to meet our high-quality and purity standards. Unlike low-purity products, which may contain other materials that don’t cut well, almandine garnet often costs more but delivers superior cutting results. They are consistent in particle size, eliminating oversize particles, which tend to clog the nozzle, and excessive fines can collect in the feed line or cutting head, causing irregular feed and sputtering in the cutting stream. We also remove dust-causing “superfines” and non-garnet materials using multiscreen filtering system and carefully measure suspended solids to ensure process cleanliness. The BARTON manufacturing process ensures consistent control of the purity and particle-size distribution in all our waterjet abrasives.

Find the best abrasive for waterjet cutting

The best way to find the best abrasive for waterjet cutting is to work with your BARTON representative. Describe the type of material you intend to cut. How thick is it? What edge quality and surface finish do you need? How many pieces do you need to produce in normal shift? Answers to these questions will help determine the best type and grade of garnet for your waterjet cutting application.