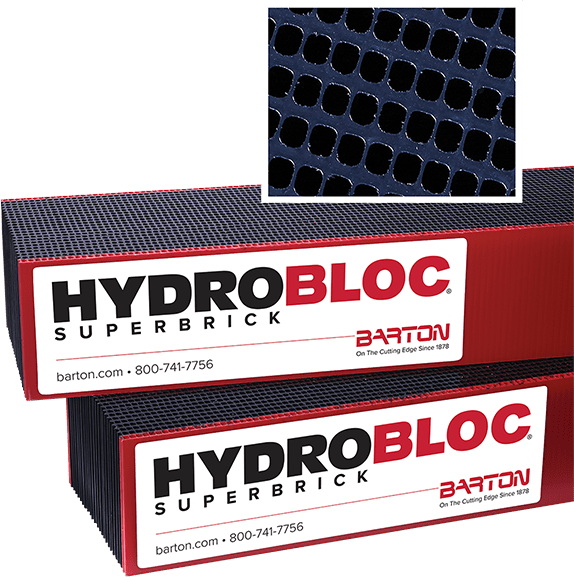

HYDROBLOC® – Waterjet Cutting Bricks

HYDROBLOC Holds Up to the Rigors of Waterjet Cutting

BARTON’s HYDROBLOC waterjet cutting bricks are specially designed and manufactured to fully support parts during the waterjet cutting process. Made in the USA with a proprietary polypropylene material, the bricks use a laminated pattern to minimize splash back from the waterjet while draining water and debris away quickly and effectively.

HYDROBLOC waterjet cutting bricks are welded and strategically screwed for superior durability.

Made in the USA and shipped from a warehouse near you.

Call to Order 800-741-7756 or Email orders@BARTON.com

Part #WX404005 (3.85″ x 6″ x 48″) | Part #WX000006 (6″ x 6″ x 48″)